Water pipe pressurization refers to the system of changing the shape of water pipes under positive conditions. it is beneficial for improving the energy and longevity of the pipe substances, making it extensively used in diverse engineering initiatives. right here is the way to perform water pipe pressurization.

how to carry out Water Pipe Pressurization

1. select appropriate Water Pipe substances

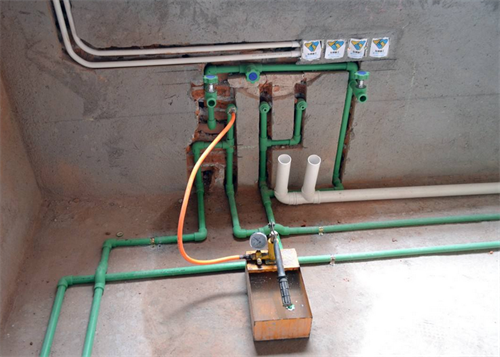

while carrying out water pipe pressurization, it's far crucial to pick out suitable water pipe materials. specific initiatives require exclusive materials, consisting of percent pipes, PE pipes, and PPR pipes. each kind of fabric has its personal applicable range for pressure and temperature, so selecting the right pipe material is important for making sure the effectiveness of the pressurization procedure.

2. control the Parameters of Water Pipe Pressurization

it's miles vital to strictly control the parameters at some stage in the water pipe pressurization method, such as temperature, strain, and pace. The pressurization temperature ought to be determined based on the melting temperature of the pipe fabric and normally kept below the fabric's melting factor. The stress and pace also want to be determined in step with the pipe's material and dimensions; excessive strain or velocity can cause harm or uneven deformation of the pipe.

3. make certain the interior of the Pipe is clean

earlier than carrying out pressurization, make certain that the interior of the water pipe is clean and free from impurities or residues. these impurities can reason uneven distribution of stress within the pipe, affecting the effectiveness of the pressurization. consequently, thorough cleaning and inspection ought to be done before the system.

4. check the surface pleasant of the Pipe

The floor pleasant of the water pipe extensively impacts the pressurization results. Any defects or dents at the floor can lead to cracks or misguided shapes after pressurization. for this reason, a cautious inspection of the pipe's floor nice need to be carried out in advance to make sure it's far smooth and free of distinguished defects.

5. layout appropriate Molds

Water pipe pressurization calls for using appropriately designed molds. the mildew design ought to take into account the pipe's size, form, and the technique of pressurization to make certain that the pipe stories uniform force, stopping deformation or damage because of choppy strain distribution.

6. ensure secure Operations

at some point of the water pipe pressurization, it's miles crucial to strictly adhere to relevant operating processes. Operators need to own the vital skills and experience and comply with protection policies to keep away from accidents or device harm resulting from flawed operations. After completing the pressurization, the consequences must be tested. various techniques can be used to check the pipe's thickness, shape, internal strain, and other indicators, ensuring that the pressurization results meet the desired standards.

In precis, the method of water pipe pressurization is complex and calls for a complete consideration of more than one factors to make certain powerful outcomes. best by strictly controlling parameters, selecting appropriate substances, designing appropriate molds, maintaining easy surfaces, adhering to safety rules, and carrying out effect checks are we able to ensure that the water pipe pressurization meets the anticipated results, making sure the exceptional and protection of engineering production.